Introduction

(DTF) printing is revolutionizing the textile industry with its innovative approach and superior results. This blog will explore the numerous benefits of DTF printing, such as its versatility, exceptional print quality, and cost-effectiveness. Additionally, we will delve into the latest advancements in DTF printing technology, highlighting how these developments are enhancing the capabilities and applications of this cutting-edge printing method.

What is DTF Printing & How It Works

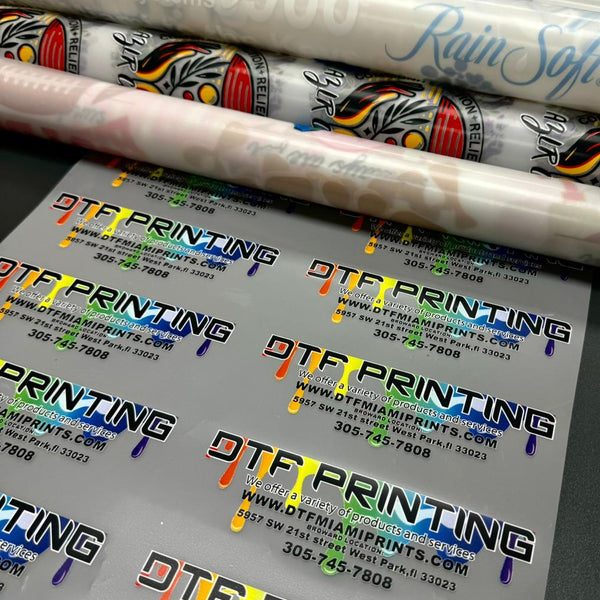

DTF printing involves transferring designs onto a special film, which is then transferred onto fabric using a heat press. This method ensures vibrant, long-lasting prints suitable for various applications.

Production Process of DTF Printing

DTF printing involves printing a design onto a transfer film using a DTF printer, which is then transferred onto garments using a heat press. The technology allows for white toner printing, creating vibrant designs on dark fabrics. This process is faster and more efficient than traditional DTG printing.

Advancements in DTF Printing

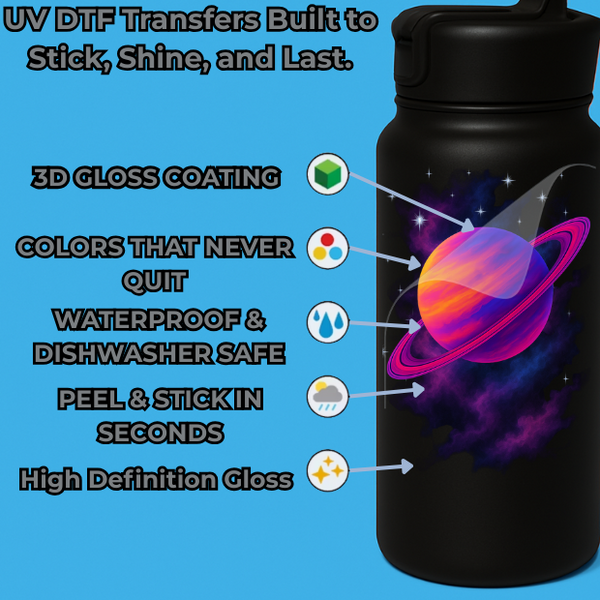

Digital Precision and Detail

- Ensures unprecedented precision, translating designs onto fabrics with unmatched accuracy and intricate details.

Direct To Film Magic

- Utilizes specialized inks directly applied to a dedicated film, enhancing clarity, depth, and color vibrancy.

Freedom from Pretreatment

- Eliminates the need for pretreatment, streamlining the process and saving time and costs.

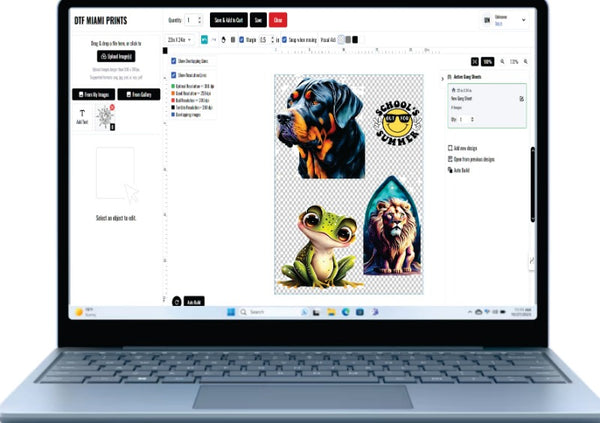

Effortless Order Placement

- Simplified order placement process via user-friendly interfaces, ensuring a seamless transition from design to print.

Integration into Hybrid Printing

- Integrates seamlessly with hybrid printing techniques, offering unique and eye-catching printing options.

Benefits of DTF Printing

Vibrant Colors

- Produces bright, bold colors that remain vivid even after multiple washes.

High Durability

- DTF prints are designed to withstand regular wear and tear, ensuring prints remain intact and vibrant.

Versatility

- Can be used on various fabrics, including cotton, polyester, and blends.

Cost-Effective

- Economical for both small and large orders, reducing setup costs and making it accessible to small businesses.

Quick Turnaround Time

- Faster than traditional methods, allowing for quicker production and delivery.

Eco-Friendly

- Uses less water and produces less waste, employing eco-friendly, water-based inks.

Ease of Use

- User-friendly process that doesn’t require extensive training or expertise.

Customization

- Allows for high degrees of customization, perfect for personalized gifts, promotional items, and branded apparel.

Applications of DTF Printing

DTF printing is versatile and can be used across various industries:

Fashion Industry

- Produces high-quality, customized apparel quickly and efficiently.

Customized Apparel

- Enables the creation of personalized t-shirts, hoodies, and sportswear.

Home Décor

- Allows for custom pillowcases, curtains, and unique wall art.

Industrial Uses

- Benefits promotional products and branded merchandise, ensuring logos and designs maintain their integrity.

Conclusion

DTF printing is a game-changer in the custom printing industry. Its ability to produce vibrant, durable, and versatile prints makes it a top choice for businesses and individuals alike. Whether for custom apparel, promotional items, or personalized gifts, DTF printing offers a reliable and cost-effective solution.

FAQs

Q1: What is the primary advantage of DTF printing over traditional screen printing?

- Greater flexibility and precision, allowing for vibrant colors and intricate designs without extensive setup.

Q2: Can DTF printing be used on materials other than fabric?

- Yes, it can be used on various materials, including non-fabric items like bags and accessories.

Q3: How does DTF printing contribute to sustainability?

- Uses less water and produces less waste compared to traditional methods, with eco-friendly inks.

Q4: Is DTF printing suitable for large orders?

- Yes, it is efficient for both small and large orders, with quick turnaround times.

Q5: What kind of designs work best with DTF printing?

- Detailed and colorful designs, making it ideal for logos, text, and intricate artwork.

Q6: How can I ensure the longevity of my DTF prints?

- Proper care, such as washing garments inside out in cold water and avoiding high heat during drying, will maintain the vibrancy and durability of DTF prints. Navigation Previous Article:

-

Hot Peel vs Cold Peel DTF Film

Next Article:

DTF Printing Materials and Techniques

Related Articles: