Introduction

DTF (Direct-to-Film) heat transfers have revolutionized the custom apparel industry by delivering high-quality prints with vibrant colors and intricate details. Valued for their versatility and ease of application, these transfers have become a favorite among businesses and hobbyists alike. However, understanding the lifespan of DTF heat transfers is crucial for ensuring that printed designs remain sharp and intact over time. This article delves into the factors that influence the durability of DTF heat transfers, maintenance practices, and tips for maximizing their lifespan.

Understanding DTF Heat Transfers

What are DTF Heat Transfers?

DTF heat transfers are a printing method that involves transferring designs from a special film to fabric using heat and pressure. This process allows for high-resolution images and complex graphics to be applied to various materials, including cotton, polyester, blends, and even challenging substrates like nylon and leather.

The DTF Printing Process

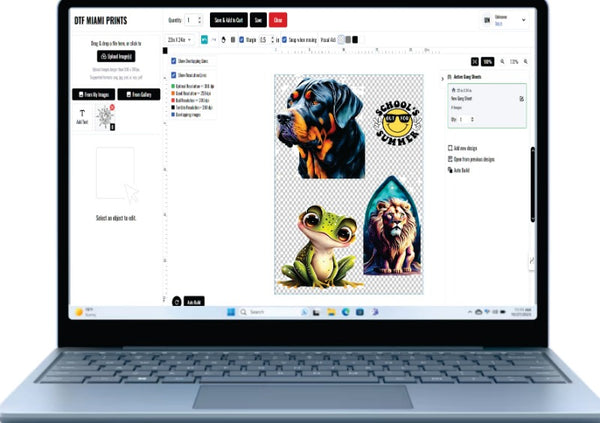

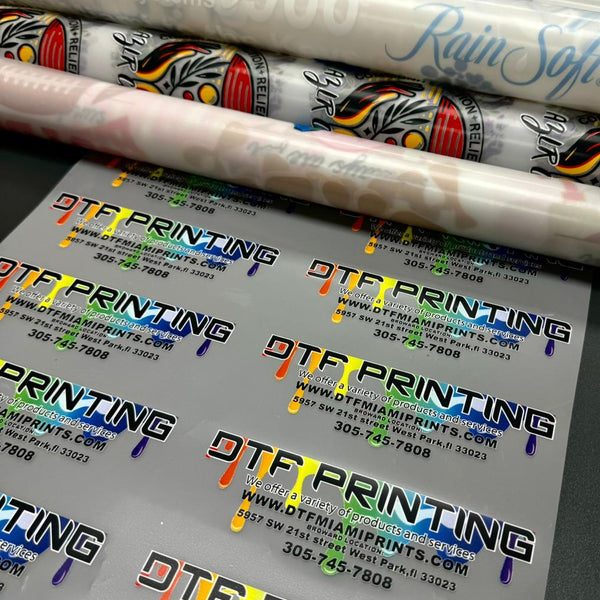

The DTF process begins by printing a design onto a polyethylene terephthalate (PET) film using a specialized DTF printer. After printing, a hot-melt adhesive powder is applied to the film, which is then cured. The final step involves pressing the film onto the fabric with a heat press, transferring the design onto the material.

Advantages of DTF Heat Transfers

DTF heat transfers offer several benefits:

- Versatility: Suitable for various fabrics and materials.

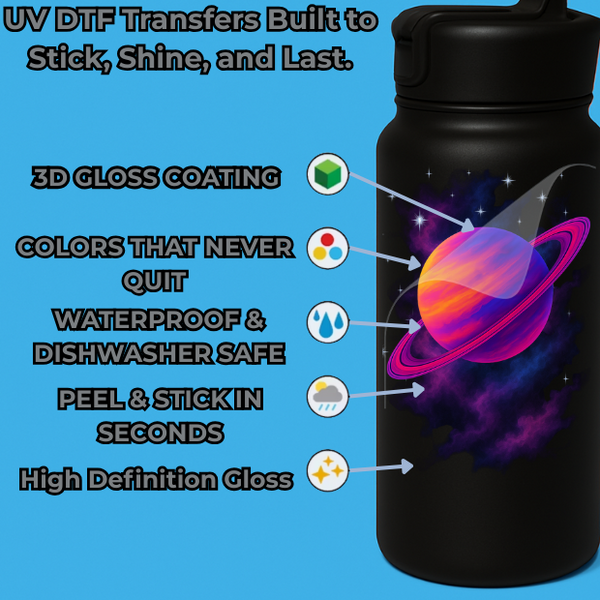

- High Detail: Capable of producing intricate designs with fine lines and vibrant colors.

- Durability: When applied correctly, DTF transfers can withstand multiple washes without significant fading or cracking.

Factors Influencing the Lifespan of DTF Heat Transfers

Quality of Materials

The longevity of DTF transfers largely depends on the quality of the PET film, ink, and adhesive powder used. High-quality materials contribute to more durable and long-lasting prints.

Application Process

The application process, including temperature, pressure, and time settings, is critical in determining the durability of DTF transfers. Incorrect settings can lead to poor adhesion, shortening the lifespan of the design.

Fabric Type

Different fabrics interact with DTF transfers uniquely. For instance, cotton and polyester generally yield excellent results, while materials like nylon may require special considerations to ensure optimal adhesion and durability.

Washing and Care Instructions

Proper washing and care are essential for maintaining the integrity of DTF transfers. Avoiding harsh detergents, washing in cold water, and turning garments inside out can help prolong the life of the prints.

Maximizing the Lifespan of DTF Heat Transfers

Choosing High-Quality Materials

Investing in high-quality PET film, ink, and adhesive powder is the first step toward ensuring durable DTF transfers. Quality materials not only improve the final appearance but also enhance the longevity of the designs.

Optimal Application Settings

Using the correct heat press settings is crucial. Typically, DTF transfers require a temperature range of 300-350°F, a pressure setting of medium to firm, and a pressing time of 10-15 seconds. Following manufacturer guidelines can help achieve the best results.

Pre-Treating the Fabric

Pre-treating the fabric can enhance the adhesion of DTF transfers. This may involve washing the fabric to remove any residues or applying a pre-treatment solution to improve the transfer's bond with the material.

Proper Washing and Maintenance

To maximize the lifespan of DTF transfers, follow these washing and maintenance tips:

- Wash Inside Out: Turn garments inside out to protect the design during washing.

- Use Mild Detergents: Avoid harsh chemicals and opt for mild detergents.

- Cold Water Wash: Wash in cold water to prevent the design from fading.

- Avoid High Heat: Refrain from using high heat during washing or drying.

Common Issues with DTF Heat Transfers and Solutions

Peeling or Cracking

Peeling or cracking of DTF transfers can occur due to improper application or low-quality materials. Ensuring correct heat press settings and using high-quality products can mitigate these issues.

Fading Colors

Fading colors are often a result of using low-quality inks or exposing the garment to harsh washing conditions. Investing in high-quality inks and following proper washing guidelines can help maintain vibrant colors.

Poor Adhesion

Poor adhesion is typically due to incorrect heat press settings or inadequate pre-treatment of the fabric. Adjusting temperature, pressure, and pressing time can improve adhesion.

The Future of DTF Heat Transfers

Technological Advancements

The DTF printing process continues to evolve with advancements in technology. Improved printers, inks, and adhesive powders are enhancing the quality and durability of DTF transfers, making them an increasingly popular choice for custom apparel.

Sustainability Considerations

As the industry grows, there is a focus on making DTF heat transfers more sustainable. This includes developing eco-friendly inks and recyclable PET films, contributing to a more environmentally conscious printing process.

Market Trends

The demand for custom apparel is on the rise, and DTF heat transfers are at the forefront of this trend. Their ability to produce high-quality, durable designs quickly and cost-effectively positions them as a key player in the custom printing market.

FAQs

What are DTF heat transfers? DTF heat transfers involve printing designs onto a special film and then transferring them to fabric using heat and pressure. This method allows for high-detail, vibrant prints on various materials.

How long do DTF heat transfers last? With proper application and care, DTF heat transfers can last for many washes without significant fading or cracking. The lifespan depends on the quality of materials used and how well the garment is maintained.

Can DTF transfers be applied to any fabric? DTF transfers work well on a variety of fabrics, including cotton, polyester, and blends. However, some materials, like nylon, may require special pre-treatment to ensure proper adhesion.

What are the common issues with DTF transfers? Common issues include peeling, cracking, and fading. These can often be mitigated by using high-quality materials, following proper application procedures, and adhering to recommended washing guidelines.

How can I prolong the life of my DTF heat transfers? To prolong the life of DTF transfers, use high-quality materials, follow the correct heat press settings, pre-treat the fabric if necessary, and adhere to proper washing and care instructions.

Are DTF heat transfers better than other printing methods? DTF heat transfers offer unique advantages, such as high detail and versatility. While they may not always be superior in every aspect, they are often preferred for intricate designs and quick production times.

Conclusion

DTF heat transfers are a game-changer in the custom apparel industry, offering unparalleled detail and vibrant colors across a range of fabrics. By understanding the factors that influence their lifespan and implementing best practices for application and care, users can enjoy long-lasting, high-quality prints. As technology advances and the market grows, DTF heat transfers are set to become an even more integral part of the custom printing landscape.

Additional FAQs

What type of heat press is best for DTF transfers? A high-quality heat press with precise temperature, pressure, and timing controls is essential for applying DTF transfers effectively.

Can I use a home iron for DTF transfers? While possible, a home iron may not provide the consistent heat and pressure needed for optimal results. A heat press is recommended for best outcomes.

Do DTF transfers fade over time? With proper care, DTF transfers maintain their color and detail over many washes, but exposure to harsh conditions can cause some fading.

Are there eco-friendly options for DTF printing? Yes, eco-friendly inks and recyclable PET films are becoming available, making DTF printing a more sustainable option.

Can DTF transfers be removed from fabric? Removing DTF transfers can be challenging and may damage the fabric. It is typically a permanent application.

Further read : How direct-to-film printing works (DTF Miami experts)