If you're exploring the best printing method for your fabric projects, you’ve likely come across two popular options: Direct to Garment (DTG) and Direct to Film (DTF) printing. While both have their advantages, DTF printing often proves to be the superior choice for various reasons. Let's dive into what makes DTF better and how it compares to DTG in an easy-to-understand way.

Understanding DTG and DTF Printing

To kick things off, let's clarify what DTG and DTF printing are all about.

What is DTG Printing?

DTG, or Direct to Garment printing, is like using an inkjet printer to print directly onto fabric. You place a shirt (or another fabric) in a DTG printer, and it prints your design directly onto the material. It's known for producing detailed images with a soft feel.

What is DTF Printing?

DTF, or Direct to Film printing, involves printing your design onto a special film first. Then, you transfer the design from the film onto the fabric using a heat press. This process involves an adhesive powder to make sure the design sticks well to the fabric.

Comparing the Processes

Both methods have their own steps, but they work quite differently.

DTG Printing Process

- Pre-treatment: You treat the fabric with a special solution to help the ink stick better and look more vibrant.

- Printing: The design is printed directly onto the fabric.

- Curing: You need to heat the fabric to set the ink.

DTF Printing Process

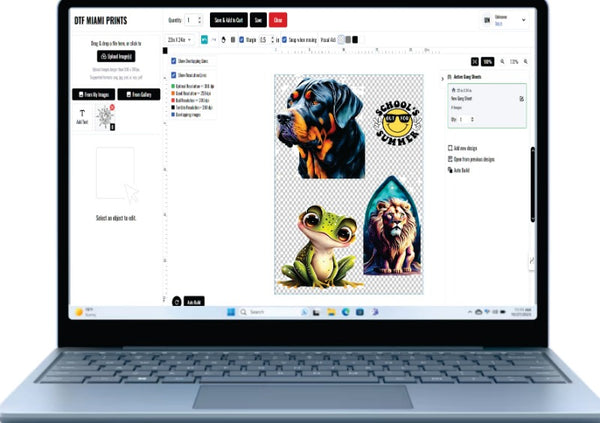

- Design Creation: Create and mirror your design using graphic software.

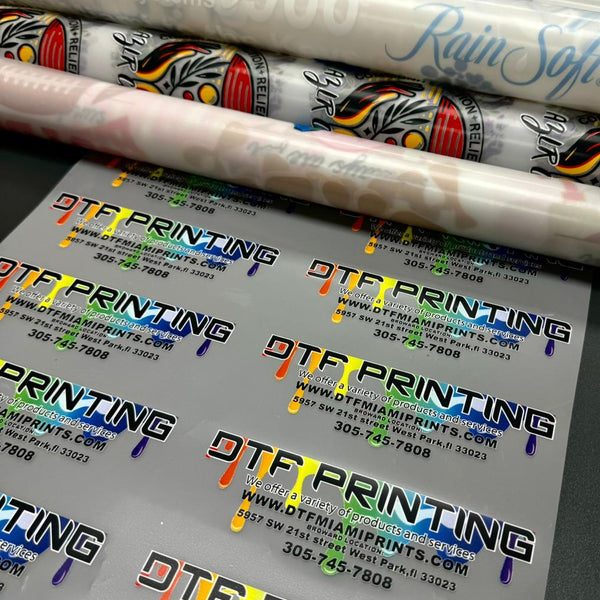

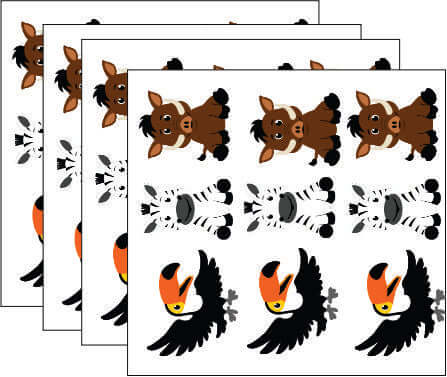

- Printing on Film: Print the design onto PET film.

- Powder Application: Apply adhesive powder to the wet ink.

- Curing: Heat the film to bond the adhesive with the ink.

- Transfer to Fabric: Use a heat press to transfer the design from the film to the fabric.

Why DTF Printing is Better Than DTG

DTF printing outshines DTG in several ways. Here’s a simple comparison to show why DTF might be the best choice for you.

Versatility and Fabric Compatibility

DTG Printing Limitations

DTG printing is mostly great for cotton fabrics. It can struggle with other materials like polyester or blends, and dark fabrics can be particularly challenging.

DTF Printing Flexibility

DTF printing works well on many types of fabrics, including cotton, polyester, blends, nylon, and even dark fabrics. This means you can use DTF for a wider variety of projects, giving you more creative freedom.

Print Quality and Durability

DTG Print Quality

DTG prints can be very detailed and soft to the touch. However, they might not last as long. Over time, the prints can fade or crack, especially if they aren’t cured properly.

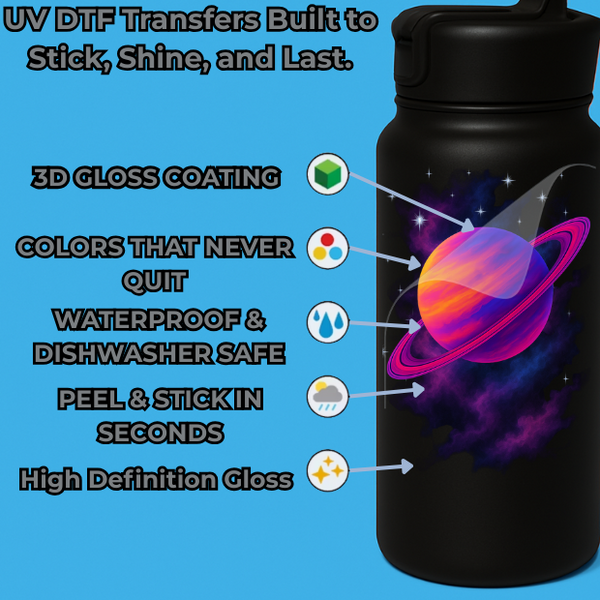

DTF Print Durability

DTF prints are incredibly durable. They don’t crack or peel easily and can withstand many washes without losing their vibrancy. The adhesive powder used in DTF printing helps the design stick firmly to the fabric, making it very durable.

Cost-Effectiveness

DTG Printing Costs

DTG printing can get expensive, especially for small runs. You need special inks, pre-treatment solutions, and maintenance can be pricey. Plus, DTG printers themselves are often quite costly.

DTF Printing Affordability

DTF printing is generally more budget-friendly. There’s no need for pre-treatment, which saves time and money. The films and adhesive powders used in DTF printing are also cheaper than the special inks required for DTG. Additionally, DTF printers tend to be less expensive than DTG printers.

Production Efficiency

DTG Printing Time

DTG printing can be slow because each garment needs to be pre-treated, printed, and then cured. This can make it difficult to handle large orders quickly.

DTF Printing Speed

DTF printing is faster. You don’t need to pre-treat the fabric, and the curing and transfer processes are efficient. This means you can produce more items in less time, making DTF ideal for meeting tight deadlines or handling large orders.

Environmental Impact

DTG Environmental Considerations

DTG printing uses water-based inks, which are better for the environment. However, the pre-treatment chemicals and the energy-intensive curing process can offset these benefits.

DTF Printing Sustainability

DTF printing is also eco-friendly, using water-based inks and producing less waste. Without the need for pre-treatment chemicals, it’s a greener choice. Plus, DTF printing tends to use energy more efficiently, further reducing its environmental footprint.

Market Applications

DTG Printing Market

DTG printing is great for small to medium-sized businesses that focus on custom apparel. It’s perfect for producing high-quality, detailed prints in small batches, making it popular for custom t-shirts, hoodies, and other garments.

DTF Printing Versatility

DTF printing can be used for a broader range of products and industries. It’s excellent for fashion, sportswear, promotional products, and even home décor items. Because it works on so many different fabrics, DTF printing allows businesses to expand their product offerings more easily.

Maintenance and Operational Ease

DTG Printer Maintenance

Maintaining a DTG printer can be challenging. You need to clean the print heads regularly to avoid clogs, and the pre-treatment process can wear down the equipment over time. This maintenance can be time-consuming and costly.

DTF Printer Maintenance

DTF printers are generally easier to maintain. Without the pre-treatment step, there’s less wear and tear on the equipment. The PET films used in DTF printing also reduce the risk of clogs in the print heads, making maintenance simpler and less frequent.

Customer Preferences and Trends

DTG Customer Appeal

Customers like DTG printing for its soft, detailed prints, especially on light-colored cotton garments. It’s ideal for intricate designs and personalized apparel.

DTF Customer Satisfaction

However, DTF printing is becoming more popular because of its durability and vibrant colors. Customers appreciate prints that last longer and look good even after many washes. The versatility of DTF printing also means customers can get custom designs on a wider range of fabrics.

Case Studies and Industry Examples

DTG Success Stories

Many small businesses have found success with DTG printing, especially in the custom t-shirt market. It’s great for producing high-quality, detailed prints in small batches. However, scaling up can be challenging due to the cost and time involved.

DTF Industry Leaders

Several companies have thrived using DTF printing. They’ve taken advantage of its versatility and cost-efficiency to expand their product lines. For example, promotional product companies use DTF to print on various items, from shirts to bags. Fashion brands also favor DTF printing for producing durable, vibrant designs that stand out.

Future Prospects

DTG Technology Developments

DTG technology is continuously improving, with advancements aimed at increasing speed, reducing costs, and expanding fabric compatibility. These developments could make DTG more competitive in the future.

DTF Printing Innovations

Meanwhile, DTF printing is also evolving rapidly. Innovations in ink formulations, film quality, and transfer processes are enhancing print quality and efficiency. As these technologies advance, DTF printing is set to become even more appealing.

Conclusion

When comparing DTG vs DTF printing, it’s clear that both methods have their strengths. However, for most applications, DTF printing stands out as the better option. Its versatility, cost-effectiveness, and superior durability make it ideal for a wide range of projects. Whether you’re a small business owner or a large-scale manufacturer, DTF printing offers the flexibility and quality you need to succeed.