Introduction

Direct to Film (DTF) transfers have revolutionized the custom printing industry, offering vibrant, durable prints that can be applied to various fabrics. However, to truly maximize the lifespan of DTF transfers, it's essential to follow proper maintenance and care practices. In this blog, we will explore key tips and best practices to ensure your DTF transfers remain vibrant and durable over time.

Understanding DTF Transfers

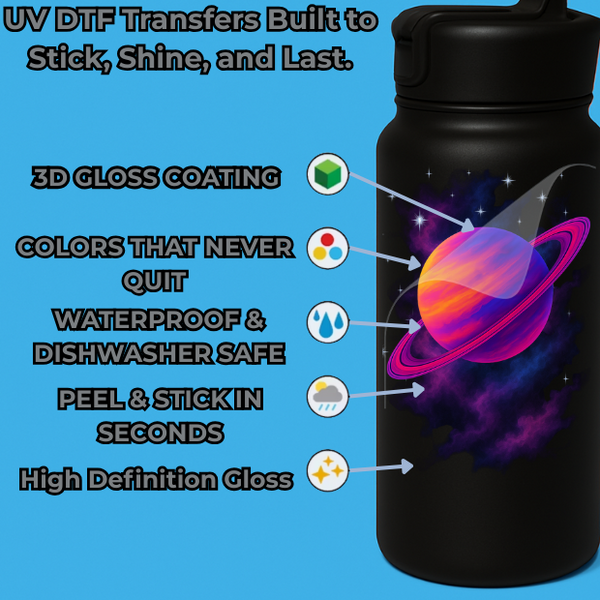

Before diving into the maintenance tips, it's important to understand what makes DTF transfers unique. DTF printing involves creating a digital design that is printed onto a special film. This film is then coated with a powder adhesive and heat-pressed onto the desired fabric. The result is a high-quality, detailed print that can withstand washing and wear.

Proper Application is Key

The first step in ensuring the longevity of your DTF transfers is proper application. Here are some key points to consider during the application process:

Use the Right Temperature and Pressure

Ensure your heat press is set to the correct temperature and pressure for the fabric you are using. Too much heat can damage the fabric and the transfer, while too little heat may not activate the adhesive properly.

Pre-Press the Fabric

Before applying the transfer, pre-press the fabric to remove any moisture and wrinkles. This creates a smooth, even surface for the transfer, ensuring better adhesion.

Cool Peel

After pressing, allow the transfer to cool completely before peeling off the film. This helps the adhesive set properly, enhancing the durability of the transfer.

Washing and Drying Tips

Proper washing and drying practices are crucial in maintaining the vibrancy and durability of your DTF transfers. Here are some tips to follow:

Wash Inside Out

Always wash garments with DTF transfers inside out. This reduces the friction and abrasion on the transfer, keeping it intact for longer.

Use Cold Water

Wash your DTF transfer garments in cold water. Hot water can cause the adhesive to weaken, leading to premature fading and peeling of the transfer.

Avoid Harsh Detergents

Use mild detergents without bleach or fabric softeners. Harsh chemicals can break down the adhesive and damage the print.

Air Dry When Possible

Air drying is the gentlest method for drying garments with DTF transfers. If using a dryer, set it to a low heat setting to minimize the risk of damage.

Storage and Handling

Proper storage and handling of garments with DTF transfers can significantly extend their lifespan. Follow these tips to ensure your transfers stay in top condition:

Store in a Cool, Dry Place

Keep your garments in a cool, dry place away from direct sunlight. Excessive heat and humidity can degrade the adhesive and cause the transfer to peel.

Avoid Folding on the Transfer

When storing garments, avoid folding them in a way that puts stress on the transfer. Rolling the garment or folding it with the transfer facing outward can help prevent cracking.

Handle with Care

When putting on or taking off garments with DTF transfers, do so gently to avoid stretching or pulling the fabric excessively. This helps maintain the integrity of the transfer.

Advanced Tips for Longevity

For those looking to go the extra mile, here are some advanced tips to maximize the lifespan of your DTF transfers:

Use a Fabric Protector

Consider using a fabric protector spray on your garments. This can add an extra layer of protection against stains and UV damage, helping the transfer stay vibrant.

Perform Test Washes

If you are producing DTF transfers for commercial purposes, perform test washes on sample garments to determine the best care instructions for your specific transfers.

Educate Your Customers

Provide customers with detailed care instructions when selling garments with DTF transfers. Educated customers are more likely to follow proper care practices, extending the lifespan of their purchases.

Conclusion

Maximizing the lifespan of your DTF transfers requires a combination of proper application, careful washing and drying, and mindful storage and handling. By following these best practices, you can ensure that your DTF transfers remain vibrant and durable, providing long-lasting enjoyment and value. Embrace these tips and enjoy the benefits of high-quality, long-lasting DTF transfers for all your custom printing needs.

FAQs

Q1: What temperature and pressure settings are ideal for applying DTF transfers?

- Use the recommended settings for your specific heat press and fabric. Generally, around 300-320°F with medium to high pressure works well.

Q2: How should I wash garments with DTF transfers to ensure longevity?

- Wash inside out in cold water with mild detergent. Avoid bleach and fabric softeners.

Q3: Can I use a dryer for garments with DTF transfers?

- Air drying is best, but if using a dryer, choose a low heat setting.

Q4: How can I store garments with DTF transfers?

- Store in a cool, dry place, avoiding direct sunlight and excessive heat. Fold with the transfer facing outward or roll the garment.

Q5: Are there any additional steps to protect DTF transfers?

- Using a fabric protector spray can add extra protection against stains and UV damage.

Navigation

Previous Article:

DTF Printing Materials and Techniques

Next Article:

Advanced DTF Printing Techniques for Professionals

Related Articles:

Achieving High-Quality DTF Prints

Hot Peel vs Cold Peel DTF Film