Direct-to-Film (DTF) printing has revolutionized garment decoration, offering vibrant and durable designs that withstand washing and wear. This guide provides a detailed walkthrough of how to apply DTF hot peel film to garments, ensuring professional-quality results. Whether you're a small business owner or a DIY enthusiast, mastering DTF printing can open up a world of creative possibilities.

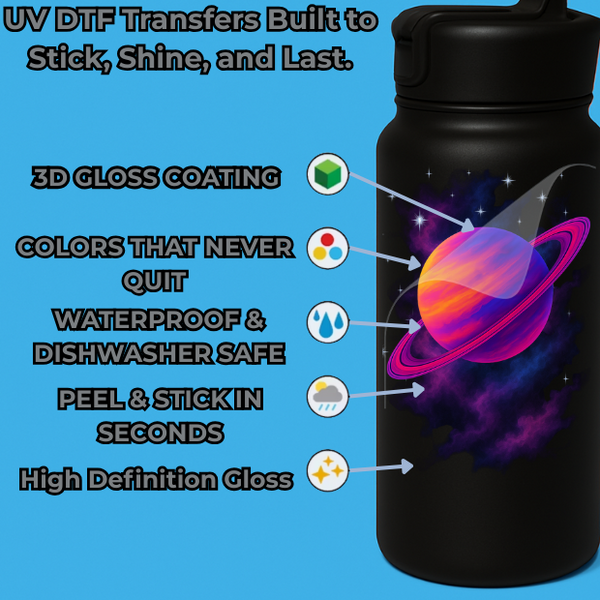

Understanding DTF Hot Peel FilmDTF hot peel film is a specialized transfer paper used in DTF printing. It allows the transfer of intricate designs and vibrant colors onto fabrics. Unlike traditional transfer methods, DTF provides excellent adhesion and durability, making it a popular choice for custom apparel.

Benefits of DTF Hot Peel Film- High Quality: Produces sharp, vibrant images.

- Durability: Designs last longer without cracking or fading.

- Versatility: Suitable for various fabrics including cotton, polyester, and blends.

- Ease of Use: Simple application process with minimal equipment.

- Temperature: Set the heat press to 300-320°F (160°C).

- Pressure: Adjust the pressure to medium.

- Time: Set the timer to 10 seconds, and once more for 5 seconds.

- Position the Film: Place the printed film onto the garment, design side down.

- Press the Film: Close the heat press and apply medium pressure for 10 seconds. Open the heat press and peel the film. Then, close the heat press and apply medium pressure for an additional 5 seconds.

- Hot Peel Method: Carefully peel the film immediately after the first 10-second press to achieve a soft, matte finish. During the peeling phase, ensure the design is not wrinkled or peeling off. If it is, you're not using enough pressure. Re-press the garment.

Cooling the Garment

Let the garment cool down for a few minutes to set the design. Allowing the garment to cool ensures that the print adheres properly and avoids any smudging.

Final InspectionCheck the design for any imperfections or areas where the film did not adhere properly. Ensuring a high-quality print is crucial for professional results.

Troubleshooting Common IssuesInk Bleeding

- Cause: Excess ink or incorrect curing time.

- Solution: Adjust ink levels and ensure proper curing.

- Cause: Insufficient heat or pressure.

- Solution: Increase heat and pressure settings. Consistent heat and pressure are key to accurate DTF transfers.

Design Fading

- Cause: Incorrect washing or drying methods.

- Solution: Follow proper garment care instructions.

Care and Maintenance of DTF Prints

- Washing: Turn the garment inside out and wash in cold water.

- Drying: Air dry or tumble dry on low heat.

- Ironing: Do not iron directly on the design; use a pressing cloth.

Tips for Professional Results

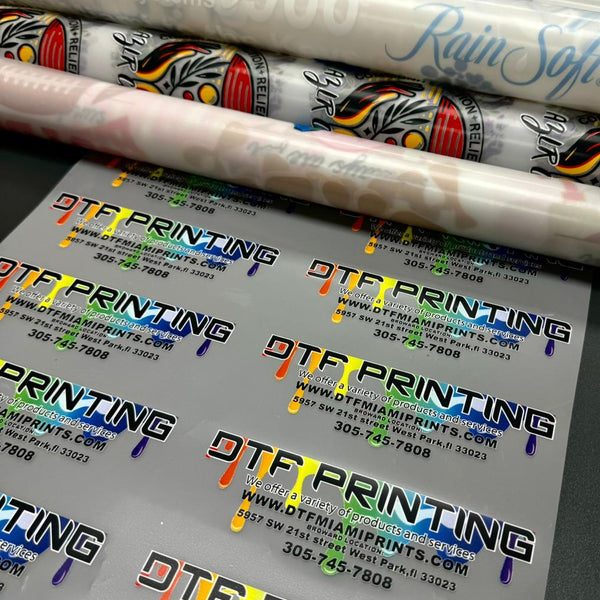

- Use high-quality DTF film and inks.

- Ensure even and adequate application of powder adhesive.

- Maintain consistent heat press settings.

Advanced Techniques for DTF Application

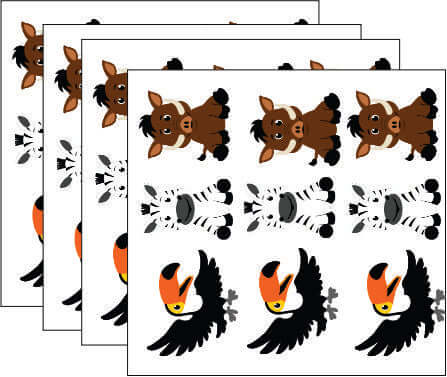

- Layering Designs: Apply multiple layers of DTF prints for complex designs.

- Combining Techniques: Mix DTF with other transfer methods like vinyl for unique effects.

- Special Effects: Experiment with glitter or metallic inks for added texture and shine.

Comparison with Other Transfer Methods

DTF vs. Screen Printing

- DTF: Better for small batches and detailed designs.

- Screen Printing: Cost-effective for large runs, but less detailed.

DTF vs. Sublimation

- DTF: Suitable for dark and light fabrics.

- Sublimation: Best for light-colored polyester fabrics.

DTF vs. Heat Transfer Vinyl (HTV)

- DTF: More detailed and complex designs possible.

- HTV: Easier for simple, single-color designs.

Frequently Asked Questions

What is DTF hot peel film?

DTF hot peel film is a transfer paper used in DTF printing that allows for vibrant, durable designs to be applied to various fabrics.

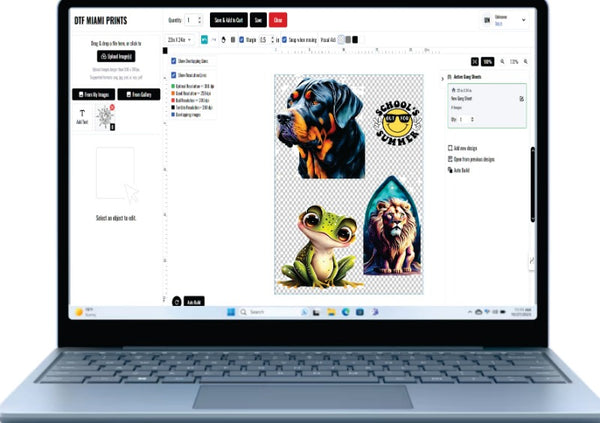

Can I use a regular printer for DTF printing?

No, you need a specialized DTF printer with the capability to print white ink.

What temperature and pressure settings should I use for applying DTF hot peel film?

Set your heat press to 300-320°F (160°C) with medium pressure for 10 seconds, followed by an additional 5 seconds after peeling.

Do I need to pre-treat the garment before applying DTF film?

Yes, pre-pressing the garment helps remove moisture and wrinkles, ensuring better adhesion of the film.

Can DTF prints be applied to any fabric?

DTF prints work best on cotton, polyester, and blends, but are not recommended for fabrics that cannot withstand heat.

How do I care for garments with DTF prints?

Wash inside out in cold water and air dry or tumble dry on low heat. Avoid ironing directly on the print.

ConclusionApplying DTF hot peel film to garments is a straightforward process that can yield professional results with the right materials and techniques. Whether you're a hobbyist or a business owner, mastering DTF printing can open up a world of creative possibilities in garment decoration.