DTF (Direct to Film) transfer sheets are revolutionizing the printing industry, providing an affordable and versatile solution for transferring high-quality designs onto a variety of materials. Whether you're a small business owner, a hobbyist, or a large-scale manufacturer, DTF sheets offer unparalleled flexibility, durability, and design accuracy. In this article, we’ll explore everything there is to know about DTF transfer sheets, how they work, and why they’re becoming the go-to choice for apparel customization and other applications.

Key Components of DTF Sheets

The effectiveness of DTF transfer sheets lies in their composition. Each sheet is made from several important components, each playing a specific role in the printing process. Let’s break down the key elements:

Polyethylene Terephthalate (PET) Film

The base material of DTF sheets is PET film, a type of durable plastic that provides flexibility and heat resistance. This film acts as a carrier for the printed design, making it easy to transfer the image onto the desired surface. PET film is preferred for its transparency and strength, allowing for precise placement and preventing the design from warping during application.

Special Ink Composition

DTF printing uses specialized inks, typically water-based pigments, that are designed to adhere to the PET film. These inks provide vibrant colors and excellent coverage, ensuring that the final print is sharp and detailed. In addition to being durable, the inks are compatible with various fabrics, from cotton to polyester, offering versatility across different types of textiles.

Hot-Melt Adhesive Powder

One of the defining features of DTF transfer sheets is the use of a hot-melt adhesive powder. After the design is printed onto the PET film, the adhesive powder is applied to the wet ink. This powder creates a bond between the design and the fabric during the transfer process. When heat is applied, the powder melts, allowing the ink to fuse with the material and ensuring a durable, long-lasting finish.

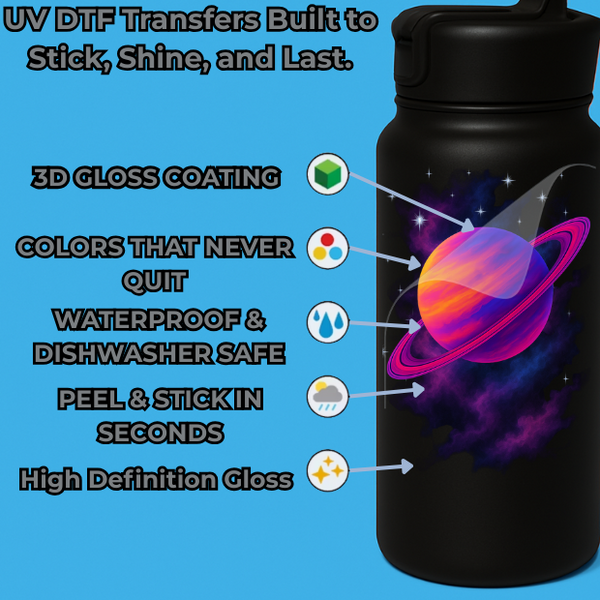

Advantages of Using DTF Sheets

DTF sheets offer numerous benefits, making them an attractive option for businesses and individuals looking for high-quality custom prints. Below are some of the key advantages:

Durability and Versatility

One of the primary advantages of DTF sheets is their durability. The hot-melt adhesive ensures that the transferred designs withstand multiple washes without fading or peeling. Additionally, DTF sheets can be used on a wide variety of fabrics, including cotton, polyester, leather, nylon, and blends, giving you greater flexibility in your projects.

Suitable for Complex Designs

Unlike some other transfer methods, DTF sheets can handle intricate designs with ease. Whether you're working with detailed patterns, fine lines, or vibrant colors, DTF transfers provide excellent resolution and color accuracy, making them ideal for complex artwork or logos.

Cost-Effectiveness for Small Batches

DTF printing is a cost-effective solution for small-batch printing, especially compared to traditional methods like screen printing, which require large setups. This makes DTF sheets an excellent choice for custom orders, prototypes, or low-volume runs where minimizing costs is essential.

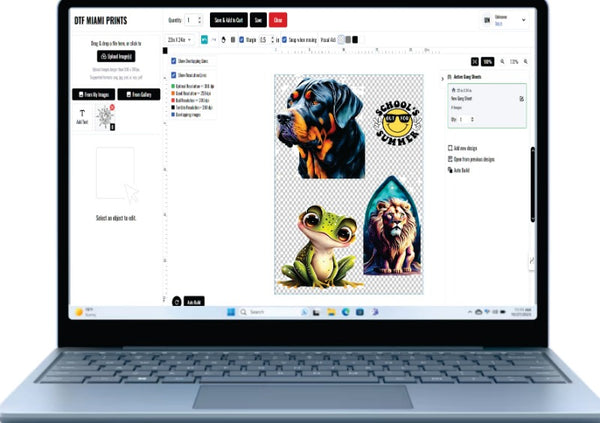

What Are Gang Sheets?

Gang sheets are a popular way to maximize the efficiency of DTF transfer printing. But what exactly are they?

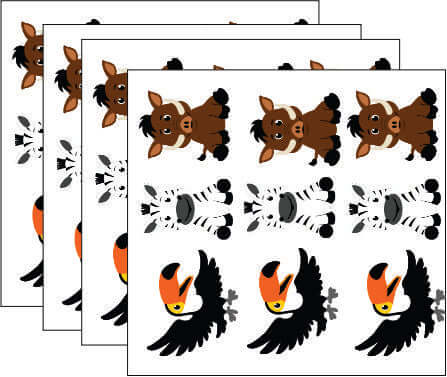

Definition and Purpose of Gang Sheets

A gang sheet refers to a single sheet that contains multiple designs printed together. This allows users to print several smaller designs on one sheet rather than using a separate sheet for each design. Gang sheets are an excellent way to save on material costs and reduce waste.

How Gang Sheets Maximize Efficiency

With gang sheets, you can combine multiple customer orders or several variations of the same design on a single sheet. This not only saves time but also lowers production costs. For example, if you're printing logos for a small business, you can fit multiple logos on one sheet and press them onto different items in one go.

Benefits of Using Gang Sheets for Bulk Orders

Gang sheets are especially useful for bulk orders, where you need to print a large number of small designs. By using one large sheet, you cut down on printing time and make it easier to manage high-volume jobs. This method is popular for businesses that produce branded merchandise, promotional items, or customized apparel.

DTF Transfer Sheet Printing Process

The process of printing with DTF sheets is straightforward, but attention to detail is key to achieving the best results. Let’s walk through the steps involved:

Step-by-Step Guide to the DTF Printing Process

- Design Preparation: First, create or choose your design, ensuring it is ready for print. You’ll need a printer compatible with DTF inks and software for managing the design.

- Printing on PET Film: Print your design onto the PET film using the special DTF ink. Make sure the print is clean and precise.

- Applying the Adhesive Powder: While the ink is still wet, apply the hot-melt adhesive powder evenly across the design. This ensures that the design will adhere properly to the fabric.

- Curing the Design: After applying the adhesive powder, the design needs to be cured. This is done by placing the sheet in a curing oven or using a heat press to set the adhesive.

- Pressing the Design: Once the design is ready, it’s placed onto the fabric, and heat is applied using a heat press. The pressure and heat cause the adhesive to melt and bond the ink to the fabric.

- Peeling the Film: After cooling, the PET film is peeled off, leaving the printed design securely transferred to the fabric.

Pre-Press and Pressing Techniques

Using the right temperature and pressure settings is crucial for a successful transfer. Too much heat can cause the ink to smear, while too little can prevent the adhesive from bonding properly. Most DTF transfers require a temperature of around 310°F (155°C) and a pressure of 30 psi for about 15 seconds. However, this may vary depending on the fabric and the complexity of the design.

Post-Transfer Care and Durability

Once the transfer is complete, proper care is essential to ensure the longevity of the design. Most DTF prints are durable and can last through 50+ washes without significant fading. To extend the life of the print, it’s recommended to wash garments inside-out and avoid using high heat when drying.

DTF vs. Sublimation Printing

When choosing a printing method, it’s important to compare DTF with other popular techniques like sublimation. Here’s a breakdown of how they differ:

Color Accuracy and Vibrancy

Both DTF and sublimation offer vibrant color reproduction, but DTF tends to produce deeper blacks and more vivid colors on a wider range of fabrics. Sublimation, on the other hand, excels in reproducing smooth gradients and photographic images but is limited to polyester-based materials.

Fabric Compatibility

One of the main advantages of DTF printing is its ability to work on a wide variety of fabrics, from cotton to polyester and blends. Sublimation is restricted to polyester or poly-coated items, which can limit its use in certain applications.

Long-Term Durability Comparison

Both methods offer excellent durability, but DTF transfers are generally more resistant to wear and tear, especially on fabrics that undergo heavy use, such as sportswear or work uniforms. Sublimation prints, while long-lasting, may show signs of wear faster when applied to certain materials.

Frequently Asked Questions (FAQs) about DTF Transfer Sheets

- What is the difference between DTF transfer sheets and regular heat transfer vinyl?

DTF (Direct-to-Film) transfer sheets differ from traditional heat transfer vinyl (HTV) in several key aspects. DTF sheets allow for more intricate designs, including full-color prints with gradients, while HTV typically involves solid colors and requires layering for multicolor designs. Additionally, DTF sheets work on a wider range of fabrics, including cotton, polyester, blends, and even leather, whereas HTV is more limited in fabric compatibility.

- How long do DTF transfers last on garments?

DTF transfers are known for their durability, withstanding 50+ washes when cared for properly. By washing garments inside-out and avoiding high heat during drying, you can extend the life of DTF prints. The durability of DTF transfers makes them ideal for high-wear garments such as uniforms or sportswear.

- Can I print DTF transfer sheets with a regular inkjet printer?

No, DTF transfer sheets require specialized printers and inks designed specifically for this process. These printers use water-based pigment inks that adhere well to the PET film, and the process involves applying a hot-melt adhesive powder to secure the print onto the fabric. Regular inkjet printers and inks are not compatible with DTF printing.

- Are DTF sheets environmentally friendly?

DTF printing uses water-based inks, which are generally more environmentally friendly compared to solvent-based inks. However, the PET film and adhesive powder used in the process are made from plastic materials, so sustainability will depend on how the waste is managed. Recycling programs for PET film and responsible disposal of used transfer materials can help minimize environmental impact.

- What types of fabrics can I use DTF sheets on?

One of the main advantages of DTF sheets is their versatility. They can be used on a wide variety of fabrics, including cotton, polyester, blends, nylon, leather, and even non-fabric items like bags and shoes. This flexibility makes DTF transfers a popular choice for a broad range of applications, from T-shirts and hoodies to promotional items and accessories.

- How do gang sheets save costs in bulk printing?

Gang sheets allow multiple designs to be printed on a single sheet, reducing material waste and lowering costs. This method is especially useful in bulk printing scenarios where you need to produce a high volume of smaller designs, such as logos or branding for uniforms. By consolidating several designs onto one sheet, you optimize material usage and cut down on production time, leading to overall savings.

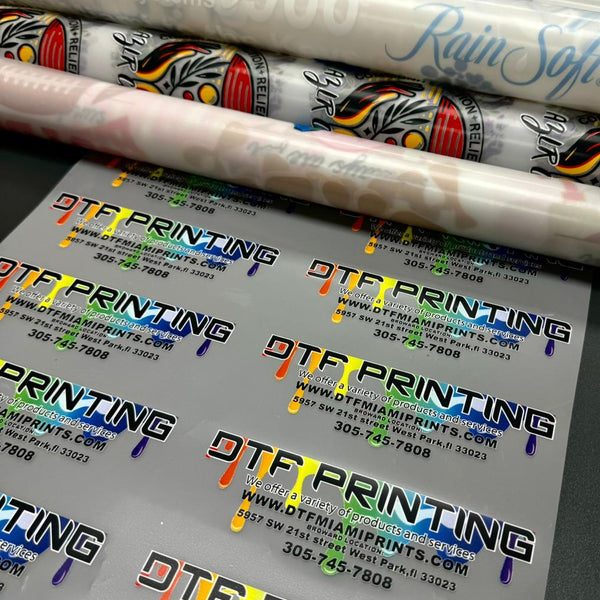

Conclusion: Why DTF Transfer Sheets Are a Game Changer

DTF transfer sheets represent a significant advancement in the custom printing industry. Their versatility, durability, and ability to handle intricate designs make them a go-to choice for businesses, hobbyists, and individuals looking for high-quality, long-lasting custom prints. Whether you're producing small batches for individual customers or handling large-scale orders for businesses, DTF sheets provide the flexibility and efficiency needed to deliver excellent results.

For those in areas like West Park, Florida, Miami, Dania Beach, Hallandale Beach, Pembroke Park, Andover, North Miami Beach, Ojus, Aventura, Cooper City, Davie, Pembroke Pines, Miramar, and Country Club, DTF Miami Prints offers top-of-the-line DTF transfer sheets and printing services tailored to meet your needs. With a focus on quality and customer satisfaction, DTF Miami Prints is your local source for custom apparel and fabric printing solutions.