Introduction

In the vibrant world of textile printing, DTF (Direct to Film) heat transfers stand out as a revolutionary technology. This technique offers versatility, superior quality, and efficiency, transforming how businesses and designers produce printed apparel and accessories. This introductory post will cover the basics of DTF heat transfers, explaining how they work and why they are increasingly popular in the industry.

What Are DTF Heat Transfers?

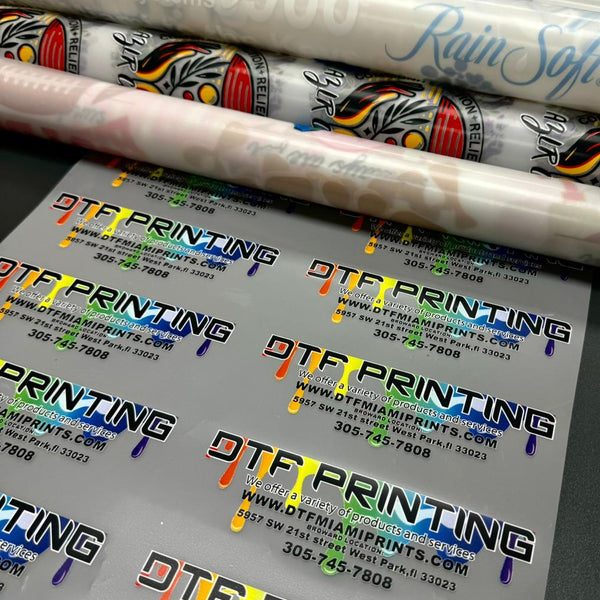

DTF heat transfers involve printing a design onto a special film, which is then coated with an adhesive powder and heat-pressed onto various materials. Unlike traditional printing methods, DTF does not require the fabric to be pre-treated, allowing for more flexibility in material choice and color application.

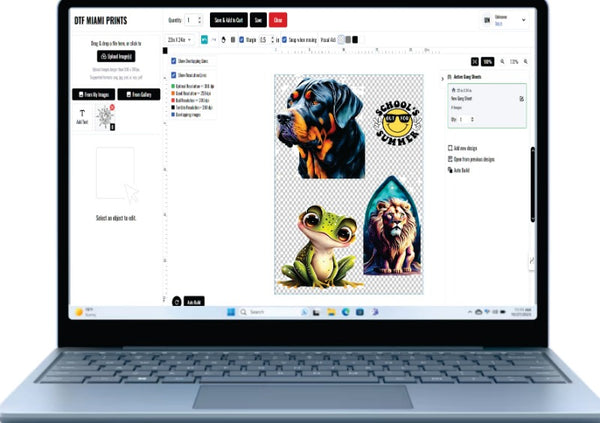

How DTF Heat Transfers Work

The process begins with the digital printing of a mirrored image onto a clear PET film. After printing, an adhesive powder is applied to the wet ink, which is then melted and dried under a heat source. The final step involves transferring the print onto the fabric using a heat press, which activates the adhesive to bond the ink to the textile, creating a vibrant, detailed print.

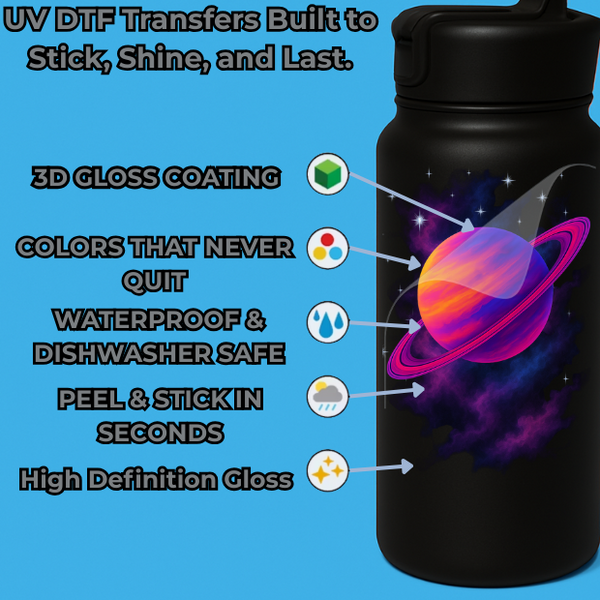

Benefits of DTF Heat Transfers

DTF printing is praised for its ability to produce vivid colors and sharp details. It is also capable of printing on virtually any kind of fabric, including synthetics that are challenging for other techniques. Furthermore, it offers excellent durability, with prints that are resistant to washing and wear.

Advantages of DTF Heat Transfers Compared to Traditional PrintingWhile traditional printing methods have dominated the textile industry for decades, DTF heat transfers are quickly gaining ground. This post will compare DTF technology to conventional techniques like screen printing and sublimation, highlighting the unique benefits that make DTF a superior choice for modern printing needs.

Cost-Effectiveness

Traditional methods such as screen printing require substantial setup, making them less cost-effective for small runs. In contrast, DTF printing eliminates the need for screens or plates, allowing for economical production of small batches with complex multi-colored designs.

Versatility Across Materials

Unlike sublimation, which works best on polyester fabrics, DTF heat transfers can adhere to a wide range of textiles, including cotton, nylon, and leather. This versatility opens up myriad possibilities for product offerings, from custom apparel to unique home decor.

Enhanced Quality and Durability

DTF prints are renowned for their color vibrancy and sharpness. The encapsulated ink within the transfer film results in bright, durable designs that resist fading and cracking better than those produced by traditional methods. This durability makes DTF ideal for items that require frequent washing or outdoor use.

Speed and Efficiency

DTF printing streamlines the production process by eliminating the drying time required in screen printing and the fabric-specific limitations of sublimation. With DTF, businesses can turn around orders quickly, meeting client demands for fast delivery.

Conclusion

DTF heat transfers offer significant advantages over traditional printing methods, including cost efficiency, material versatility, superior quality, and operational speed. As the industry continues to evolve, DTF stands poised to become the preferred choice for businesses looking to optimize their printing operations.